Here’s what you need to know about ceramic coating

Search the internet for ceramic coating and you will find a lot of different terms. One even more beautiful than the other. Some of these terms are based on Mohs' scale of mineral hardness. 9H, 11H and even 13H, we've already seen it pass. What does that H stand for? Let's go back to the beginning.

The hardness of ceramic coating: what exactly is that?

Friedrich Mohs was the creator of mohs’ so-called scale of mineral hardness. He came up with this scale in 1812. Until then, minerals were not judged for hardness, but on composition.

Hardness is the resistance of a solid material, for example the car paint, against distortion by pressure or rub forces.

See the video for more explanation about Mohs scale of mineral hardness.

There are several ways to measure hardness, namely the Mohs scale, Ridgway’s scale and Wooddell’s scale. However, all these measurement methods are not very suitable for measuring the hardness of a ceramic coating.

That’s why the American Society for Testing and Materials (ASTM) method for measuring film and ceramic coatings has been created. This is done using the Pencil Scale.

Hardness scale for ceramic coatings: the Pencil Scale

The Pencil Scale is therefore actually a special hardness scale for ceramic coatings. It is just one of the many tests to evaluate coatings. Other tests such as wear, oxidation, gloss retention, UV resistance, drying times and chemical resistance (both acid and alkaline) are also very important for the end result.

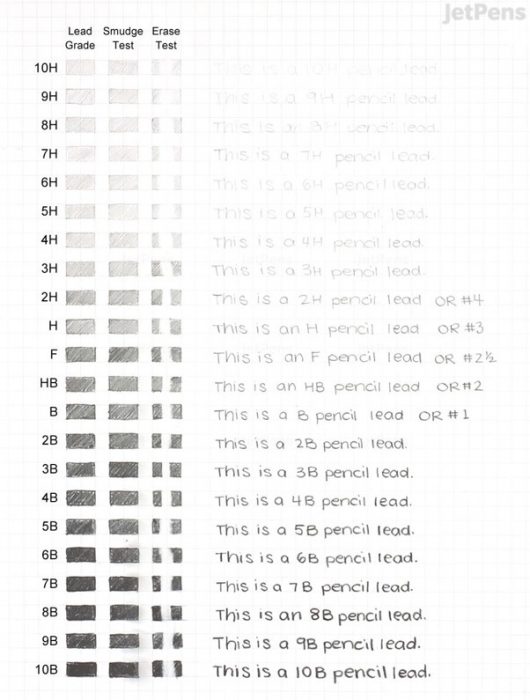

Pencils are in different shapes and sizes. You can buy them yourself in the store. Grab a pencil. Chances are you’ll find an H or HB code on it. Pencils are available in different ranges of hardness, from 10H to 10B. The range of pencils starts at 10B (very soft) and rises to 10H (very hard). See the image for the effect of these pencils.

How the ceramic coating hardness test works

A pencil with a certain hardness is selected. It is fixed at an angle of 45 degrees in a so-called Pencil Grade Tester and is placed on the surface. Then, with continuous pressure, a line of about 2 centimeters long is made. When the pencil scratches the surface of the ceramic coating, a softer pencil is used until we get the first pencil that does not scratch.

The current clear lacquer of a car have a hardness of between 1 and 4 on mohs’ scale. Ceramic coatings claim to improve this hardness to 9H. Measured with mohs’ scale, this would mean that the lacquer becomes as hard as diamonds, with the result that there can be no scratch in the lacquer anymore. Unfortunately, this is not the case and this is where the confusion and deception comes from. 9H talks about the Pencil Hardness Test, which should not be confused with the scale of Mohs.

The truth behind ceramic coating

So a ceramic coating can still be scratched. There’s no 9H pencil going to change that. Unfortunately, the paint of the car will not turn into an armor that you can only scratch with a diamond.

Nevertheless, a ceramic coating offers a lot of benefits. The car gets a long-lasting protective layer that makes the paint less scratch sensitive. In addition, the glass coating makes it easier to wash, protects it from contamination, acids and UV radiation. And even though a good ceramic coating like Ceramic Guard is not as hard as diamond, it gives at least the same gloss.

Ceramic Guard

Become a Ceramic Guard specialist? Get trained by one of our experienced experts and discover how your company can make the difference with Ceramic Guard.