Which car polisher do I have to choose?

Polishing machines are available in all shapes and sizes. At Cartec we know everything about it, in our product range you can find up to 25 of them. There are three different types of motions in the market at the moment, which are the basis of the polishing process. Per type a brief explanation.

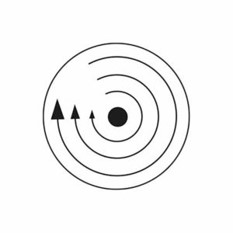

1. Rotary polishing machine

This is the oldest machine among the three. The rotary polisher rotates on an axis. At a certain number of revolutions, this axis generates a certain speed. Let’s say 1000 RPM (revolutions per minute). And of course there is a polishing sponge holder on the axle, and a polishing pad on the polishing sponge holder. Because the circumference on the outside of the pad is larger than on the inside of the axle, the number of revolutions on the outside is higher. This creates the well-known holograms (polishing strips). Herein there is a danger that the paint can be burned quickly. A rotating machine grinds away a lot of paint in a short time. The advantage is that scratches can be removed more quickly. For heavy paint repair jobs, this machine is very suitable in combination with a coarser compound.

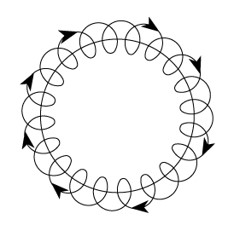

2. Dual action / eccentric polishing machines

In 2008, the brand Rupes first launched an eccentric polisher on the market. This machine is driven by a weight in the front of the machine. This creates a range of between 12 and 21 mm. The advantage of this range is that each time a different part of the paint is touched, which makes polishing more egalitarian. This results in less hologram formation, the paint gets hot less quickly and the paint gets damaged less quickly. The ‘cutting effect’ is achieved by the polishing sponge holder that starts to rotate in the range of between 12 and 21 mm. There is a downside to this as well. Without the right technique (pressing too hard, pad not straight on the paint) the polishing sponge holder can stall (stand still) and the polishing effect is minimal. Nevertheless, with the right technique, pads and polishing paste you can achieve very good results with this machine as well.

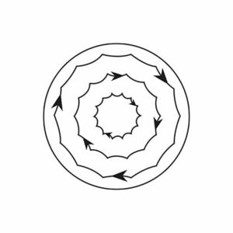

3. Gear driven polishing machines

This is a combination of the rotating and dual action machine. With this machine, both the rotation and the range of 5 to 8 mm are driven by a gear. The main advantage of this machine is that it cannot be pressed still by the user. The disadvantage of this machine is that it does not excel in a particular area. Removing holograms, for example, is much easier with an eccentric machine, while removing scratches is much better done with a rotating machine. In regard of effect, the gear driven polishing machine is hanging in between a rotating and an eccentric machine.

Do you want to know more about how to remove scratches? See this article: ‘How to remove scratches from a car’s paintwork’

Summary

A clear overview of all the advantages and disadvantages:

Which polishing machine is favourite completely depends on the user. As displayed in the overview, every machine has its pro’s and cons. The advice is to start testing for yourself!